Product Application

Frieze Board

Belco XT® frieze board is primed and preservative-treated, offering anti-rot, superior moisture protection, enhanced curb appeal, and top of wall protection for long-lasting beauty and durability.

BELCO XT® FRIEZE BOARD

Top of Wall Protection

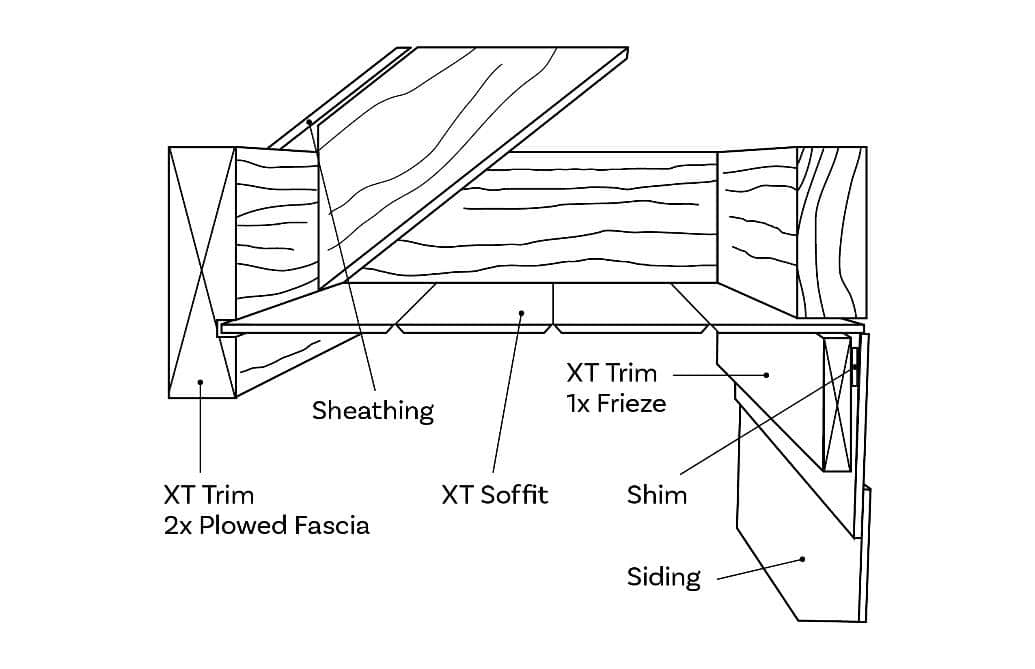

Frieze board might not be the most noticeable part of your home’s exterior, but it’s one of the most functionally important. Positioned where siding meets soffit, frieze boards protect structures from moisture, pests, and wear while enhancing its overall appearance. It does all this while also supporting roofing materials, helping to secure roof overhangs and extend their lifespan.

Additionally, it helps to cover and protect the gap between the siding and the underside of the soffit and is necessary to prevent moisture from seeping down beneath your siding. Despite its subtle presence, a high-quality frieze board is essential for both function and aesthetics.

Not all frieze boards are created equal. That’s why dealers and builders choose Belco XT Trim for its superior durability, low maintenance, and ease of installation.

FORM MEETS FUNCTION

Belco XT Solutions: Architectural Detailing

Belco XT frieze board is engineered to provide the perfect balance of aesthetic appeal and robust performance. Designed to meet the practical needs of modern construction, Belco offers a versatile product that functions as both a protective element and an architectural highlight. With sharp square edges that deliver clean, crisp shadow lines, each board creates a sleek finish that elevates the curb appeal of any home or commercial project.

Frieze board may also be used as a decorative, horizontal trim anywhere in or on the home. It enhances architectural detailing and provides a finished look to the exterior by trimming out and hiding the cut edge of the siding at the top of the wall.

INSTALLATION BEST PRACTICES

Application and Installation Information

Belco XT frieze board is designed to simplify the installation process while offering exceptional longevity and curb appeal. Choose a long-lasting frieze board option with minimized build site effort, and maximized time management and profit. It is normally installed flat against the home, but it may be installed at an angle if used on a gable.

Cost-Effective and Efficient Installation

Like all of the Belco XT Products, one of the standout benefits of Belco frieze board is its single-step installation process. It is lightweight in nature, allowing for single person installation, and requires no special fasteners or tools.

Arrives Onsite, Ready to Use

Each Belco XT frieze board comes appearance-graded and is primed on all six sides, arriving on-site ready to go! Installing frieze boards is a straightforward process that ensures a polished and professional result. Simply measure, cut, and install. Once in place, seal the edges with caulk and fill any nail or screw holes for a seamless appearance. Finally, apply a touch-up coat of paint and clean up any debris to complete the installation.

COMMON SIZES

Typical Frieze Board Sizes

Belco XT® frieze board is available in various sizes to fit various architectural designs and project needs.

View our standard sizes below.

- 1x2

- 2x2

- 5/4x4

- 5/4x6

COMMON MATERIALS

Frieze Board Material Options

Builders have material options for frieze ranging from traditional raw wood like cedar or pine, PVC, or composite materials; but each material has its drawbacks. Traditional wood, such as cedar or unfinished pine, offers a classic look but requires frequent maintenance and is prone to rot, decay, and insect damage. PVC is low-maintenance and resistant to pests, but it can warp in extreme temperatures and lacks the authentic appearance of wood. Composite materials strike a balance between durability and aesthetics but can fade over time, and they’re often more costly than other options, and require special tools and fasteners.

Belco XT frieze board offers a superior solution by combining the timeless appeal of natural wood with modern durability. Our preservative-treated design resists rot, decay, and pests, outperforming untreated wood and withstanding the elements better than PVC or composite. Easy to cut, and install, and finish with the desired top-coat, Belco ensures a flawless, low-maintenance finish that enhances any home. With Belco, you get the perfect blend of beauty, performance, and long-lasting value.

THE BELCO DIFFERENCE

Built to Last

Belco XT® Trim offers long-lasting performance thanks to our proprietary 2-step treatment process. First, Belco’s non-metallic, EPA-approved wood preservative treatment (Wolman® AG) penetrates the wood fibers and is then properly dried before priming. This key distinction is what sets us apart, ensuring our wood is fortified from within. Our proprietary, industry-leading water-based primer protects the surface and resists water penetration. The end result? Trim and frieze board products with unmatched durability exceed the highest industry standards for coating consistency and wood substrate quality.

PROTECT YOUR INVESTMENT

Belco XT® Frieze Board is Backed by an Industry-Leading Warranty

We wholeheartedly stand behind the quality of our products. We go the extra mile when it comes to ensuring the longevity of our products. Belco XT Trim is a durable one and done anti-rot solution that undergoes a proprietary two-step treatment process to protect the wood against damage from moisture, decay, and insects. Our products are so durable and long-lasting that they come with an industry-leading, non-prorated 20-year warranty. Protect your investment by registering your products with us after purchase.

Latest Blog Posts

Complete your Home’s Look with the Right Frieze Board Trim

Trim is an important part of every siding installation. The right trim can help hide the edges of siding and cover gaps where two angles

Belly Band Trim-What It Is & Where To Use It

Where To Use Belly Band Trim Believe it or not, belly band trims can make or break the appearance of a home. You don’t want

Fascia Board: Best Practices and Regional Considerations

Fascia is the workhorse of a roof system. It ties the rafters together and keeps the gutter system intact during rain events. It is common

FAQs

At every butt or scarf joint, installers should apply a premium, flexible paintable exterior caulk, leave a small gap (typically at least 3/16 “) for movement, and then top-coat the entire board with two coats of 100% acrylic latex exterior paint within 60 days of installation (as required in Belco’s installation guide). Field cuts or exposed ends must also be primed with 100% acrylic latex primer. When you treat joints this way and employ corrosion-resistant fasteners, you block water from seeping behind siding and down into the sheathing, help preserve the integrity of the top-of-wall transition, and uphold the 20-year non-prorated warranty.

Yes, Belco frieze board is fully compatible with rain-screen cladding systems, provided that standard best practices for drainage and ventilation behind the cladding are followed. The preservative-treated, primed wood substrate performs well in this scenario because it’s engineered to resist rot, decay, and insect damage while offering a clean horizontal trim line that ties cladding, siding, and soffit together. When used in a rain-screen application, ensure the frieze board fastens to structural framing or sheathing, that flashing is installed above horizontal elements, and that the rainscreen cavity behind the siding remains clear for air circulation. The result is the aesthetic of wood with the long-term durability required in modern ventilated wall systems.

Because Belco’s frieze board undergoes a deep-penetrating Wolman® AG preservative treatment followed by factory priming of all six sides, the board arrives on-site ready to accept standard exterior adhesives and sealants without concern for inhibition or corrosion of fasteners. The metal-free, non-corrosive preservative system means there’s no need for special fasteners or adhesives, and the factory primer ensures excellent adhesion of field-applied caulks and paints. Installers should still follow manufacturer instructions for adhesives/sealants, but they can trust that the substrate is stable, dry, and engineered for long-term performance. Check out our Installation Guide and learn more about Belco’s Two-Step Preservative Treatment

Yes. The robust appearance-grade SPF substrate in Belco XT® Trim is strong enough to serve as a mounting base for light fixtures, decorative signage, or other surface-mounted elements, as long as proper installation practices are followed. Mounting points should align with structural backing or framing, fasteners must be corrosion-resistant, any field-cut holes or penetrations should be sealed with 100% acrylic latex primer and exterior paint, and flashing or sealant should be used where the fixture meets the frieze board to prevent water intrusion. Because the frieze board itself is preservative-treated and primed, it maintains its structural integrity and appearance over time, even when supporting mounted elements.