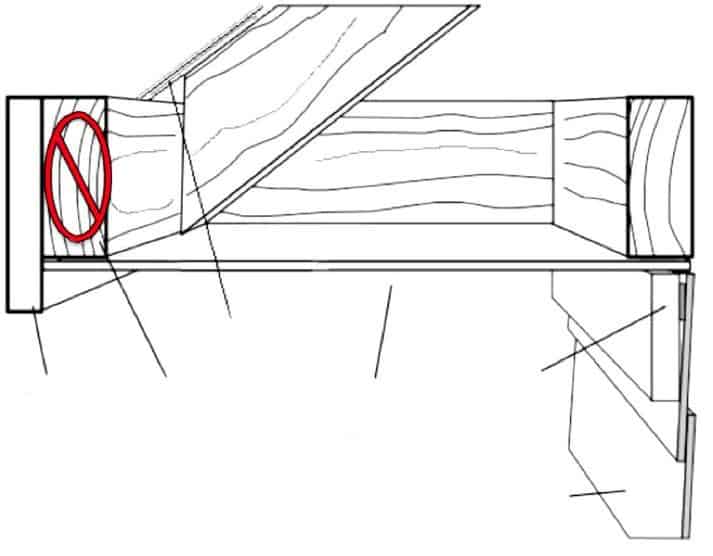

It’s important to know when to eliminate subfascia. When trimming out the rafter tails and closed soffits, many trim manufacturers rely on the load carrying capacity of 2x lumber or subfascia to complete the structural boundary of the roof. And to provide a solid substrate for the final fascia board as shown in Figure 1.

Though not required by building codes, the reasons for subfascia have more to do with evening out the rafter tail irregularities and providing structural support for the roof edge and gutters. Not all rafter tails are exactly the same length. So, applying thin profile trim products such as fiber cement, extruded vinyl, aluminum and engineered wood, may lead to an unsightly ripple effect along the roof line.

Another reason many trim manufacturers include 2x subfascia in their installation details is for gutter support. A typical rain event can impose hundreds of gallons of water into the gutter system, and the fascia must be able to support this load! Most gutter manufacturers offer details for mounting their product directly to structural fascia. A solid 2x fascia provides the required fastener penetration thickness, and superior holding power over non- structural decorative trim products.

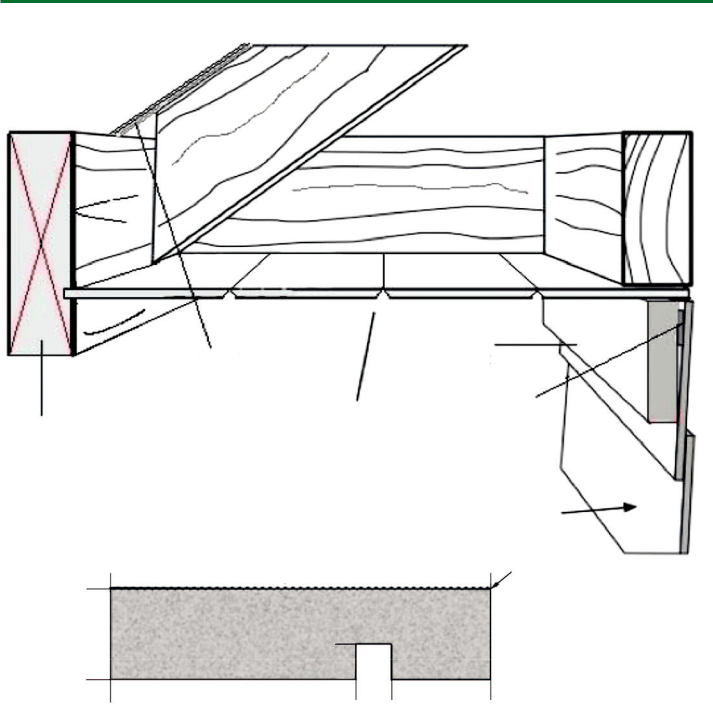

Cut labor, lumber and learn when to eliminate subfascia

As detailed in Figure 2, Belco XT® Trim, a solid wood treated trim fascia, offers a significant competitive advantage over other decorative trim products. Installing a single element XT 2×8 cuts labor and material usage in half. This can reduce a typical fascia system cost by as much as 30%. XT 2×8 also provides a cleaner line to uneven rafter tails and retains the beauty of a natural wood look. While it’s not always possible, it’s important to know when to eliminate subfascia.