Wood preservative has been around for centuries. In fact, Coal-tar creosote was patented as a preservative treatment in 1836. Dr. Karl Wolman was a pioneer in wood preservation. He first patented a fluoride-based preservative in 1907.

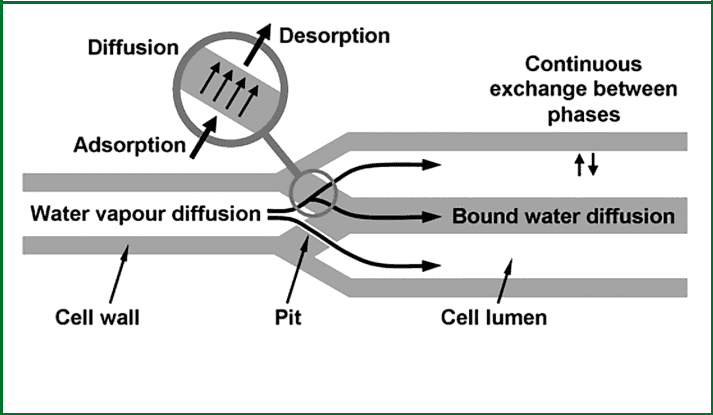

Water in Wood – A Diffusion Process

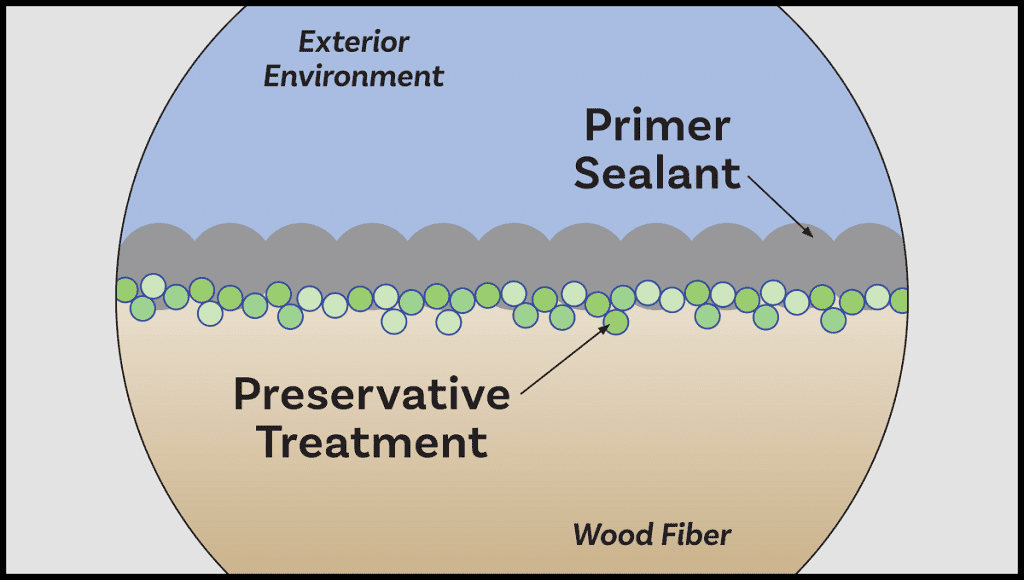

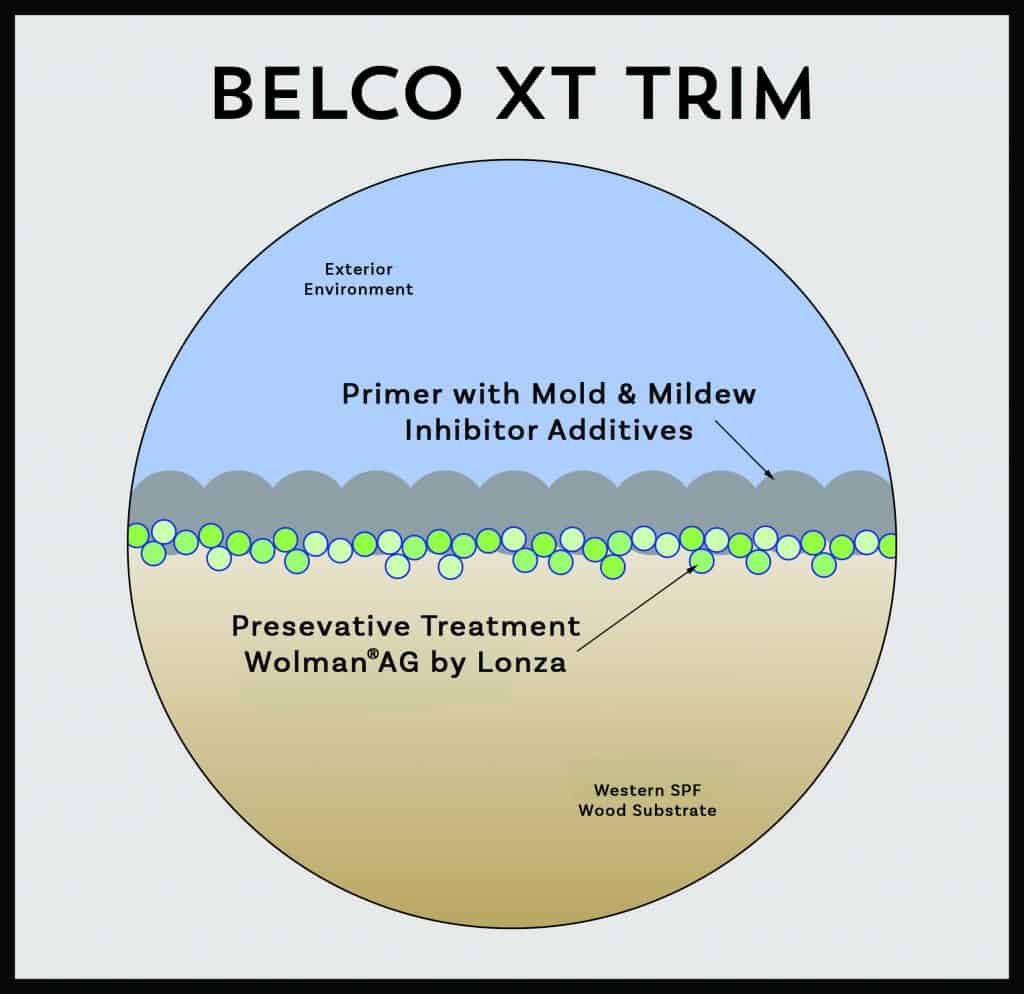

Wood is hygroscopic. So, it attracts and holds water molecules from the surrounding environment. Water vapor diffusion is the process in which all non-pressurized wood preservative treatment delivers treatment chemicals through. This means replacing the water in wood cells with the preservative chemical. Additionally, preservation is primarily concerned with sapwood. This is the outer layer directly beneath the bark. This is the physiologically active part of the wood and most susceptible to decay. However, not all water needs to be replaced to be effective.

But when the lumber is dried, next a water-based solution is applied to deliver the treatment chemicals. This happens because the force of diffusion draws the moisture into the fiber and delivers the preservative ingredients that stay when the moisture evaporates.

Within the wood cells are two types of water. Bound water is held within the cell wall by absorption forces. And free water exists as either condensed water or water vapor within the cell cavity. The Fiber Saturation Point is the point at which all free water is removed from the cell cavity and the cell walls are fully soaked. Diffusion forces determine the movement of free water from the cell cavity to the cell walls as the exterior environment draws moisture to the material surface for evaporation into the environment.

Why Wood Preservatives Work

Diffusion forces determine the movement of free water in fiber cells and thus the movement of a preservative into the cell cavities.

Additionally, to ensure that this action can take place and the sapwood accepts a water-based preservative such as Wolman AG, moisture content should be at or below 20% moisture content.

Concerns about the health and environmental impacts of metallic wood preservatives have created a market interest in non-metallic treatment product. For example, PropiconazoleTebuconazole-Imidacloprid, better known as PTI.

(For a deeper dive into diffusion in wood products-click this link) https://www.fs.fed.us/pnw/pubs/pnw_gtr676.pdf

Preservatives Improve Performance

PTI treated wood products are very well adapted for paint and stain applications with no bleed-through.

PTI treated wood products are no more corrosive than untreated wood and are approved for all types of metal contact, including aluminum. Wolman® AG (PTI) preservative, is a carbon-based treatment listed with the EPA. This product has earned a listing in the GreenSpec® directory of environmentally preferable products.

For more information on preservative treatments click this link