Few things shrink a builder’s bottom line faster than switching materials for momentary “top line” cost relief. Any savvy business mind will tell you that gross profit and net profit margins are not created equal, and neither are exterior trim materials. Issues like warping or rot in exterior trim can quietly eat into your time and budget. Exterior millwork might seem like a small detail compared to framing or roofing, but it’s often the most visible (and the most vulnerable) to climate, moisture, and time.

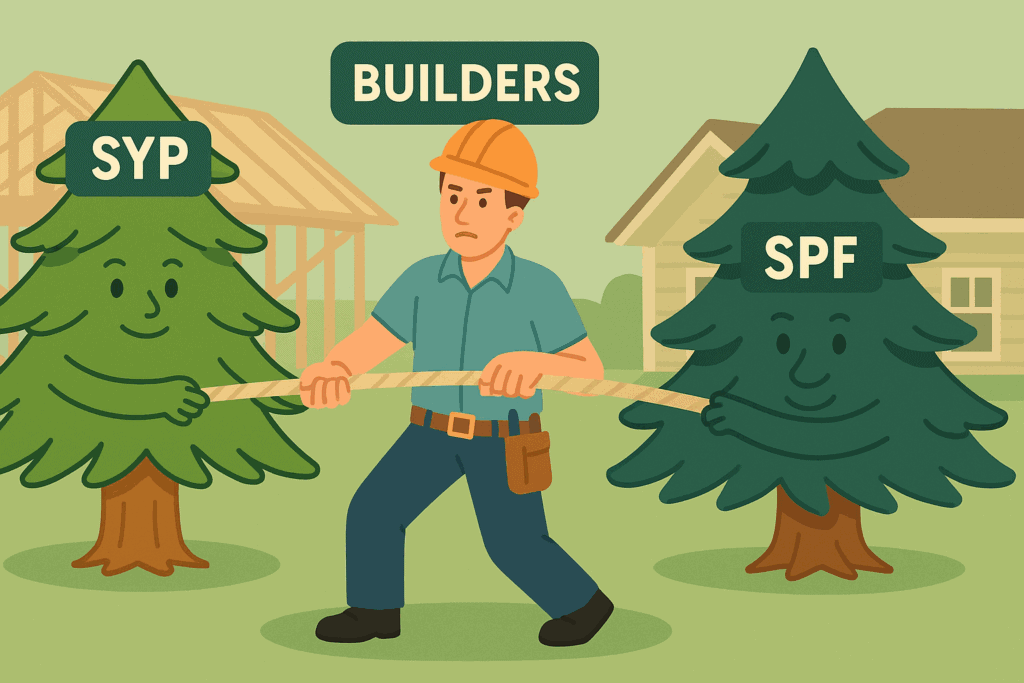

In today’s market, rising costs and supply pressures have builders looking toward Southern Yellow Pine (SYP) as a tempting alternative for exterior trim. Moreover, this year’s uncertainty around U.S. tariffs and anti-dumping duties on Canadian softwood lumber has forced many to reconsider their wood sourcing strategies. But can SYP truly perform well as exterior trim, especially in terms of rot resistance and long-term reliability?

Before switching exterior trim materials, consider these fundamental differences between the wood species, and how they perform best in their own application lanes.

Why Builders Are Considering Southern Yellow Pine

Policy Shifts Reshaping Decisions

With continual federal policy shifts regarding tariffs and duties on Canadian lumber, SYP has gained attention due to its domestic abundance and its recent potential for lower upfront cost. After all, the first two quarters of 2025 have required nearly unprecedented resilience and strategic agility from players in the construction industry. Lumber industry adjustments including the possibility of Canadian producers relocating south, further indicate the viability of this trend. However, the perceived value of initial savings could be a dicey prospect when selecting materials for exterior trim applications.

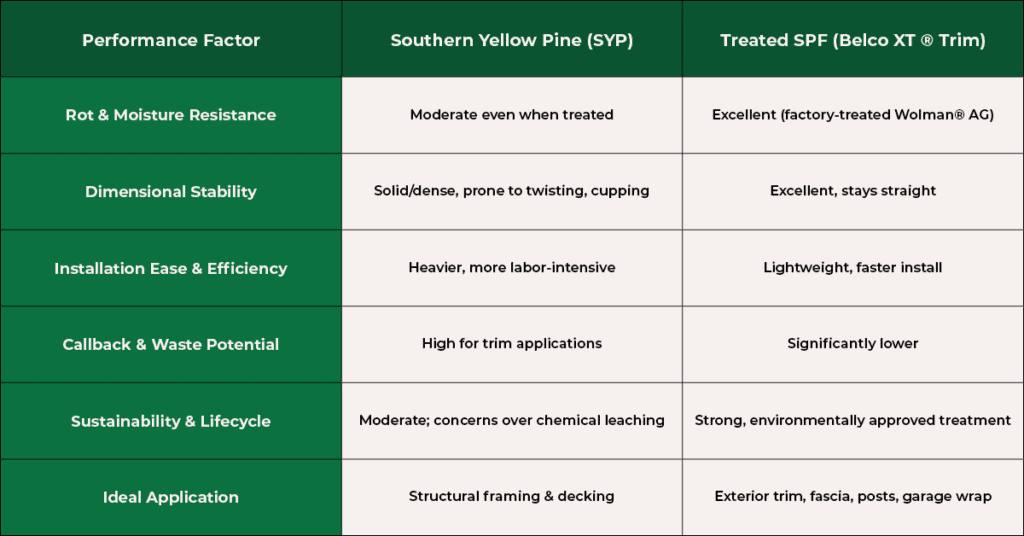

The Reality of Southern Yellow Pine Rot Resistance

SYP accepts pressure treatment exceptionally well and has many inherent qualities that make it ideal for load bearing applications. However, because it naturally tends to absorb and release moisture, it is susceptible to rot, mold, and rapid deterioration, particularly under humid or wet conditions. Even pressure treated SYP remains prone to dimensional instability. Twisting, cupping, and warping create significant callbacks and jobsite inefficiencies when used for applications like fascia or window trim. Keeping pressure treated and raw SYP boards squarely in their ideal lanes is the way. Otherwise, SYP placed where SPF should be is asking for trouble.

Regional Climate Factors: SYP Struggles Where SPF Excels

Another important consideration for exterior lumber applications is regional weather patterns. Southern Yellow Pine can be reactive in extreme climates. In the South, high humidity causes SYP to absorb and release moisture unevenly, leading to warping. This escalates directly into costly callbacks, unusable material, inventory acclimation time constraints, and ultimately, wasted material. In northern regions, repeated freeze-thaw cycles accelerate decay, even in pressure-treated boards, because SYP’s denser grain holds more moisture. One builder on Fine Homebuilding forums contributes, SYP “warps and bows in the sun big time,” making it unpredictable for trim exposed to the elements.

By contrast, Spruce-Pine-Fir (SPF) is inherently lighter, straighter, and dimensionally stable, shrinking and swelling far less across varying humidity levels. SPF’s smooth, consistent grain also retains finishes better, reducing paint cracks and seam separation over time. Properly kiln-dried and preservative-treated SPF delivers reliable rot resistance and long-term stability across climates, outperforming SYP for exterior trim needs.

Why SPF is the Superior Exterior Trim Choice

SPF lumber is straight-grained, dimensionally stable, lightweight, and highly workable. These are essential qualities for fascia, window trim, garage wrap, and more. This consistency along with its lighter weight and better receptivity to fasteners significantly reduces labor and installation time, improving jobsite efficiency.

Belco XT® Trim: Game-Changing Protection

Belco XT Trim takes the inherent performance of SPF and elevates it to another level. Using kiln-dried lumber, Belco treats every stick with Wolman® AG preservative, and then primes on all six sides, delivering extraordinary rot resistance and stability. This two-step treatment process arrives on grade, on time, and ready to install, preventing falldown, callbacks, and unnecessary replacements.

Financial Impacts: Protecting Your Margins

At every step of the supply chain, Belco’s XT family of SPF trim products are created with maximized value and net profit in mind. While SYP might initially offer a tempting alternative in these present industry conditions, hidden costs can quickly eat into margins. Even one significant callback can offset multiple projects’ material savings.

Belco XT Trim ensures faster and easier installs, longer lasting beauty and performance, and customizable finishes for various regional climates and architectural styles. These combined benefits quickly outstrip any initial perceptions of material cost savings, and ensure sustained profitability.

Choosing the Right Exterior Trim Material

Taking into account the unique confluence of 2025 market pressures, considering Southern Yellow Pine for trim applications is understandably tempting. However, its vulnerabilities to moisture, rot resistance, and stability make it unsuitable for exterior trim. Builders, dealers, and distributors who prioritize maximized net-profit recognize the clear advantage of properly preservative treated SPF lumber, and will likely keep pressure treated SYP for applications where it truly shines; framing and decking.