When builders first got their hands on pressure-treated lumber, it was a construction industry game-changer. The innovative process of forcing waterborne chemicals deep into wood fibers under high pressure suddenly meant that posts, beams, and deck framing could resist years of weather-related rot, fungal decay, and insect damage. In the appropriate applications like structural framing, ground-contact posts, and heavy-duty outdoor builds, pressure-treated wood still shines. It’s strong, readily available, and in many cases, the only lumber material that makes sense.

However, not every exterior application calls for those specific strengths. In the exterior “finish zones” of a build (i.e., fascia, soffit, posts, garage door casing, corner and window trim, and decorative millwork in general), the needs and treatment preferences shift. Here, appearance matters. Dimensional stability matters. Ease and durability of the finish coat matters. And that’s where surface preservative-treated wood steps into the spotlight.

While both treatments share the goal of protecting wood from rot, decay, and insects, they approach this goal differently. Pressure treatment uses copper-based solutions like alkaline copper quaternary (ACQ) or micronized copper azole (MCA) to penetrate the lumber, while preservative treatment (like Belco’s two-step process utilizing Wolman® AG) offers an innovative non-metallic option for excellent results without the toxic environmental impacts.

Understanding that overlap is the key to making the right call: pressure-treated where it’s the champion, preservative-treated where it’s the specialist. The distinctions ensure that builders maximize performance in every part of the build.

What is Pressure Treated Wood

Pressure-treated lumber originated from one simple idea: make wood last longer by protecting it from the elements that make it most vulnerable. The process of pressure treating forces a mix of chemicals and waterborne preservatives deep into the wood fibers using high-pressure equipment, creating a protective barrier from the inside out.

Southern yellow pine is the go-to species for this process because of its ability to absorb treatment so thoroughly. Over the years, various preservatives have been used; most notably chromated copper arsenate (CCA), once the standard for decades. Environmental concerns over CCA’s leaching potential led to modern formulations like alkaline copper quaternary (ACQ), micronized copper azole (MCA), and copper oxide–based blends, all designed to guard against decay fungi and insect damage. MCA, for example, uses tiny copper particles to lodge deep in the wood’s structure, offering strong protection while using less copper than older methods.

The result of these innovations is wood that succeeds in resisting rot and termites. It is widely available, relatively affordable, and comes in a full range of dimensions for framing stock and decking boards. This makes it a staple for applications requiring ground-contact, structural, and heavy-duty exterior applications.

The Problems with Pressure-Treated Wood

For all its performance dominance over non-treated lumber, pressure-treated wood isn’t a one-size-fits-all solution, particularly when it comes to exterior finish work. Here are a few obstacles:

Appearance Challenges

The copper-based preservatives that give PT lumber its durability often leave a greenish hue or uneven discoloration. In high-visibility applications like fascia, soffit, corner and window trim, or porch posts, that color can bleed through light paints and stains, forcing extra prep or additional coats to get a consistent finish. Additionally, southern yellow pine (SYP) tends to be a knottier species, which can negatively impact curb appeal.

Hardware Corrosion

Chemicals such as alkaline copper quaternary (ACQ) and micronized copper azole (MCA) can be highly corrosive to standard fasteners. Without stainless steel or hot-dipped galvanized hardware, builders risk premature hardware failure, which can compromise structural integrity and lead to profit-diminishing callbacks.

Health and Handling Concerns

While more modern chemicals are safer than the chromated copper arsenate (CCA) that was once widely used, cutting or sanding PT lumber still releases dust containing copper compounds. This requires extra care in handling, as well as proper disposal, often under regulations for treated wood waste.

Dimensional Stability

Pressure treatment saturates the wood during processing. Even after drying, PT lumber can be prone to warping, twisting, or splitting over time, especially in thinner profiles used for decorative applications.

These issues don’t diminish PT lumber’s value for ground-contact, framing, or structural use. But they do highlight why builders often turn to surface preservative-treated products in exterior millwork where appearance, stability, and ease of finishing are just as valuable as protection from the elements.

What Is Surface Preservative-Treated Wood?

The Importance of True Preservative Treatment

Surface preservative-treated wood products approach protection from a few different angles. It is worth mentioning here that not all preservative-treated wood is created equal. In fact, the phrase “preservative treatment” can describe anything from a simple surface primer (designed to prevent moisture intrusion from the outside in) to advanced processes that penetrate the wood fibers for deeper, longer-lasting protection.

Some trim manufacturers rely solely on prime coat sealants, which can help in the short term but leave the interior of the board unprotected against decay fungi or insects. Others use topical preservative coatings that bond to the surface but don’t address moisture intrusion or internal vulnerabilities and can even trap moisture inside, hastening decay. These methods can be sufficient for sheltered applications, but they’re not as reliable in exposed exterior conditions.

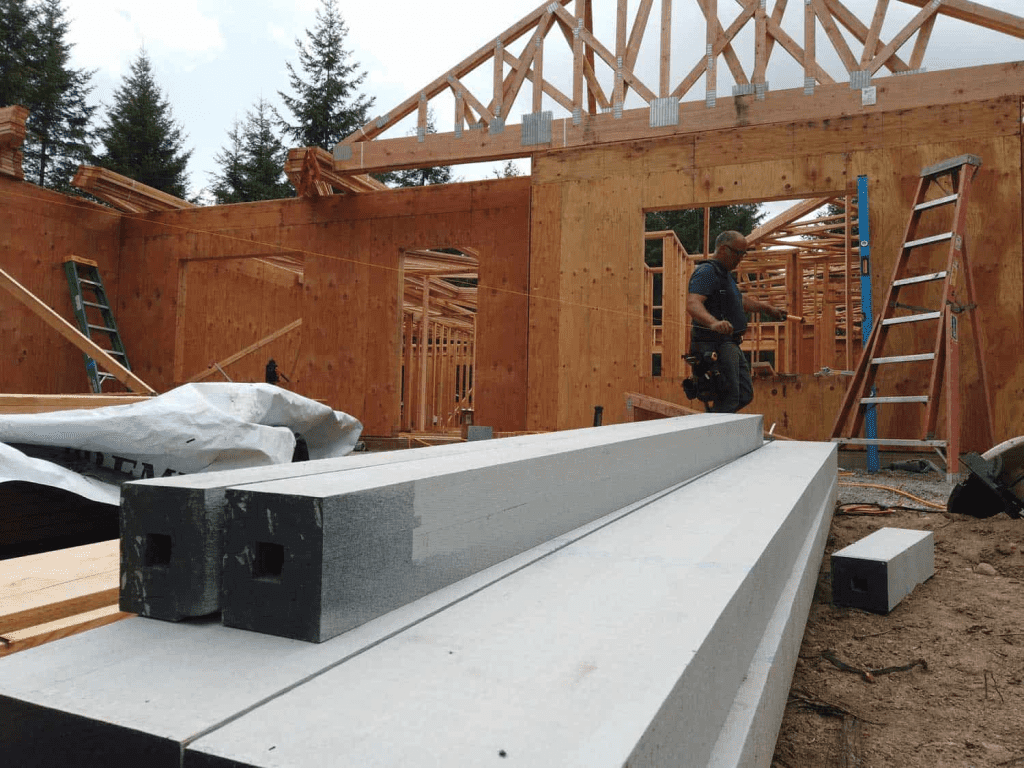

Belco’s Two-Step Treatment

Belco Forest Products takes a more comprehensive and innovative approach. Every board begins as kiln-dried, appearance-grade SPF lumber, ensuring outstanding dimensional stability and beauty from the start. Investing in higher-quality raw material impacts the end result, both functionally and aesthetically. Next, Wolman® AG preservative is applied. This is a non-metallic, low-toxicity formula that penetrates the wood fibers to protect against decay, mold, and insect damage. This wood is properly dried before the last step. Finally, each piece receives Belco’s proprietary, water-based prime coat on all six sides, sealing in the treatment and creating a smooth, ready-to-finish surface.

This true two-step treatment process delivers protection from the inside out, maintains a clean, consistent appearance, and reduces common finish failures like peeling paint or uneven coating. While preservative-treated products aren’t intended for ground contact or heavy structural framing, they excel in “finish zone” applications like fascia, soffit, corner boards, porch posts, and other decorative exterior millwork like window trim. Builders know where protection, appearance, and dependability all matter.

Glossary of Terms: Preservative-Treated vs Pressure-Treated Distinctions

To summarize, wood treatments (whether pressure or preservative-based) are employed to protect against the main enemies of exterior lumber use: decay, fungi, mold, and damage from insects. But the type of chemicals and treatment methods used often vary depending on the intended application, whether that’s ground-contact framing, decking, utility poles, or exterior trim finishing. Here’s a simple table of terms and distinctions to help clarify:

| Term | What It Means (At a Glance) | Common Uses |

|---|---|---|

| Pressure Treatment (PT) | Treated under high pressure with chemicals (typically waterborne preservatives) that penetrate deep into the wood fibers for long-term protection against decay fungi, mold, and insects. | Best for ground-contact, structural framing, decking substructure, fence posts. |

| Topical Preservative Coating | A surface-applied chemical treatment without pressure. Provides some above-ground protection but doesn’t penetrate the core. | Short-term protection for sheltered or low-exposure components. |

| Sealer / Prime Coat | A surface coating, designed to repel moisture and prepare wood for paint or stain. Doesn’t function as a preservative unless chemically enhanced or paired with another substrate treatment. | Used on trim, fascia, siding, and decorative millwork for finish prep. |

| Wolman® AG Preservative | Belco’s preservative of choice. A non-metallic, low-toxicity formula that penetrates wood fibers to guard against decay, mold, and insects without the corrosion, discoloration, or disposal issues of copper-based formulas. | Ideal for exterior millwork like fascia, soffit, corner boards, and porch posts. |

| Alkaline Copper Quaternary (ACQ) | Copper-based, waterborne preservative effective against decay fungi and termites. | Common in residential decking, fencing, and structural ground-contact applications. |

| Micronized Copper Azole (MCA) | Uses micro-sized copper particles for protection while using less copper than older formulas. | Above-ground and ground-contact PT lumber. |

| Copper Oxide–Based Blends | Broad-spectrum copper formulations to resist fungi and insects. | Exterior PT lumber in structural or deck framing. |

| Chromated Copper Arsenate (CCA) | Formerly the industry standard; phased out of most residential uses due to arsenic concerns. | Now limited to industrial products like utility poles and marine pilings. |

| SPF (Spruce-Pine-Fir) | A mix of species with fine grain, light color, and good stability. Often kiln-dried before treatment. | Common in preservative-treated millwork, trim, fascia, and siding. |

| SYP (Southern Yellow Pine) | Dense, strong species that absorbs treatment readily. | The dominant species for pressure-treated structural lumber, decking, and posts. |

Get the Right Material for the Job

The best and most long-lasting builds happen when every material is matched to its ideal purpose. Pressure-treated lumber remains the no-nonsense champion for structural, load-bearing, and ground-contact applications where deep, chemical penetration is non-negotiable. But for the high-visibility finish zones, the balancing of both form and function comes into play.

That’s where surface preservative-treated SPF products, like Belco XT®, come in, bringing inside-out protection, dimensional stability, and a clean, primed surface ready for a finish coat. It’s the right balance of performance and appearance, thoughtfully designed to cut down on jobsite labor cost, long-term maintenance, and builder callbacks.

| Application | Best Choice | Why |

|---|---|---|

| Ground-Contact Posts | Pressure-Treated (PT) — typically SYP with ACQ or MCA | Deep chemical penetration resists decay fungi, termites, and moisture over long-term soil contact. |

| Structural Framing | Pressure-Treated (PT) — SYP | High strength and load capacity; treatment reaches the core for maximum protection. |

| Deck Framing / Joists | Pressure-Treated (PT) — SYP | Designed for high-moisture, load-bearing environments. |

| Fascia | Surface Preservative-Treated (SPF) — Belco XT® with Wolman® AG | Stable, primed on all six sides, no greenish tint; resists decay and insects without fastener corrosion. |

| Corner Boards | Preservative-Treated (SPF) — Belco XT® | Dimensional stability and finish-ready surface for visible vertical trim. |

| Porch Posts (Glulam) | Preservative-Treated Glulam — Belco XT® Post | Inside-out protection, primed finish, glulam & load bearing. |

| Garage Door Casing | Preservative-Treated (SPF) — Belco XT® | Holds paint, resists swelling and splitting from moisture exposure. |

| Decorative Exterior Millwork/Window Trim | Preservative-Treated (SPF) — Belco XT® | Clean appearance, stability, and long-term finish performance. |

Contact an expert at Belco Forest Products for your next project.

FAQ's: Pressure-Treated vs. Preservative-Treated Wood

1. What is pressure-treated wood?

Pressure-treated lumber is wood placed in a sealed chamber where waterborne preservatives are forced deep into the fibers under high pressure. This process helps the wood resist moisture, decay fungi, and insects, making it a staple for ground-contact and structural applications.

2. How is lumber pressure-treated?

The lumber is placed into a pressure cylinder, flooded with a chemical preservative solution (commonly ACQ, MCA, or copper oxide blends), and then pressurized to drive the chemicals deep into the wood fibers.

3. What is preservative-treated wood?

Preservative-treated wood typically refers to lumber that has been treated with surface and/or penetrating preservatives to protect against decay and insects. The phrase “preservative-treated” can cover a wide variety of treatment processes, from penetrative to simple surface sealants. Belco’s Wolman® AG infused two-step process penetrates the wood fibers, resulting in a very stable and reliable board. It’s then sealed with a proprietary six-sided prime coat, creating finish-ready boards ideal for fascia, trim, posts, and garage wrap.

4. What’s the difference between pressure-treated and preservative-treated wood?

They differ in respective optimal wood species, treatment processes, and ideal applications. Pressure-treated wood is typically SYP (Southern Yellow Pine) and utilizes high-pressure chemical infusion for heavy-duty protection, making it ideal for structural framing. Preservative-treated wood is a broader category that may include simple surface sealers or primers applied by the manufacturer. Belco’s approach is unique. Each stick is kiln-dried appearance-grade SPF, treated with Wolman® AG (a non-metallic preservative that penetrates the wood fibers), and then prime coated on all six sides creating a finish-ready product specifically designed for trim, fascia, and exterior millwork.

5. When should one use pressure-treated wood vs. preservative-treated wood?

Use pressure-treated SYP when the wood will touch the ground or carry structural loads (like deck framing or fence posts). Use preservative-treated SPF for high-visibility finish areas (fascia, corner trim, porch posts, window trim, garage wrap) where stability and a clean, paint-ready surface matter most.

6. Is pressure-treated wood stronger than untreated lumber?

No. Pressure treatment doesn’t make the wood structurally stronger. It increases resistance to decay and insects. The strength comes from the species itself.

7. What chemicals are in pressure-treated wood?

Modern formulations often include alkaline copper quaternary (ACQ), micronized copper azole (MCA), or copper oxide. Older products used chromated copper arsenate (CCA), which has been phased out of residential use due to arsenic concerns.

8. Is pressure-treated wood safe?

Today’s pressure-treated wood is considered safe for residential use, but it should be handled with care. Wear a mask when cutting, and never burn scrap due to chemical content. For applications where workers and homeowners frequently touch the surface, preservative-treated trim offers a safer, cleaner, more environmentally conscious option.

9. What species are used for treated lumber?

SYP (Southern Yellow Pine): Dense and absorbs treatment exceptionally well, which is why it’s the primary species used in pressure-treated lumber. Some builders do choose SYP for exterior trim, but its tendency to warp, cup, and struggle with moisture makes it far less stable than SPF.

SPF (Spruce-Pine-Fir): Lighter, more stable, and ideal for preservative-treated trim and millwork where appearance and finishability matter.

10. Can non-pressure-treated wood be used outside?

Yes, but it depends on the application. Untreated wood exposed to the elements will quickly absorb moisture, warp, and decay. If you’re building outdoors, use pressure-treated lumber for structural ground contact applications, or preservative-treated lumber for trim and fascia to ensure long-term performance.