Advances in wood treatment and forest management practices often begin from the efforts of stubborn optimists who refuse to accept the limitations of the status quo. Change agents often see “industry standard” as a phrase that warrants curious investigation and expansion. As Belco observes National Forest Week, we spotlight the progress made in sustainable forestry and the technological strides that are redefining how the world utilizes one of our most vital renewable resources: wood. The next generation of wood treatment processes and responsible forestry redefines what wood can do. A more innovative and sustainable lumber industry can deliver breakthrough wood products and systems, while regenerating the natural ecosystems we depend on.

History of Wood Treatment and Why it Matters

Industrialization and increased global reach fueled the pursuit of building materials that last longer, creating a cultural phenomenon toward more “permanence”. Along the way this gave rise to wood alternatives such as composites, fiber cement and engineered plastics. These products do resist rot and weather wear, but they also come with trade-offs that compromise the integrity of our invaluable eco-systems: higher embodied energy, VOC emissions, and landfill accumulation to name a few.

In contrast, one of wood’s greatest assets may be its impermanence as a result of its natural beauty. As a renewable, biodegradable resource, responsibly harvested and properly treated wood offers a more circular and sustainable life cycle. With advancements in treatment technology, wood can remain a competitive solution with longer-lasting materials, without leaving behind the same environmental footprint.

However, while versatile and renewable, wood is inherently vulnerable to moisture, insects, and decay. The instinct to fortify and improve its longevity is as old as evolving civilization itself. Ancient Egyptians used oils and resins to preserve wooden structures, and in the 19th century, the practice of treating railroad ties with creosote became common. But it wasn’t until the early 20th century that modern wood treatment, especially pressure treatment, became mainstream.

Apart from dramatically extending the lifespan of timber products, reducing waste, and indirectly conserving forests by maximizing wood’s utility, enhanced wood durability means less frequent replacements, reduced forest resource demands, and a smaller environmental footprint overall.

Historically, two primary treatment methods have dominated in the industry:

Pressure Treatment

Pressure treatment as we know it today was primarily industrialized in the 1930s and 40s. The treatment method was especially useful in the booming post-war construction era, when durability and scale became more important. By the 1950s and 60s, pressure-treated wood had become a staple for utility poles, decks, and foundations across North America. However, it wasn’t long before concerns began to surface. Many formulations included arsenic, chromium, or copper, substances effective against decay but potentially harmful to humans and ecosystems. By the early 2000s, regulatory and public pressure led to the phase-out of chromated copper arsenate (CCA) for most residential uses, marking a shift toward safer treatment technologies.

Surface Treatment

Surface treatments such as sealants and stains, have long been used to protect and beautify wood. While easier to apply, they lack the deep-penetrating protection of pressure treatment and require pesky maintenance schedules for reapplication. These limitations, along with rising environmental awareness, have been the precursors to innovation, driving demand for more environmentally responsible and longer-lasting solutions.

Advanced Innovations in Wood Treatment and Modern Forestry

As sustainability values culturally evolve and construction demands increase, innovation in wood treatment and forestry has been challenged to “meet the moment”. These advancements have the power to dramatically transform forest management, material manufacturing, and our entire built environment. Let’s look at a few:

1. Eco-Friendly, Non-Metallic Preservatives

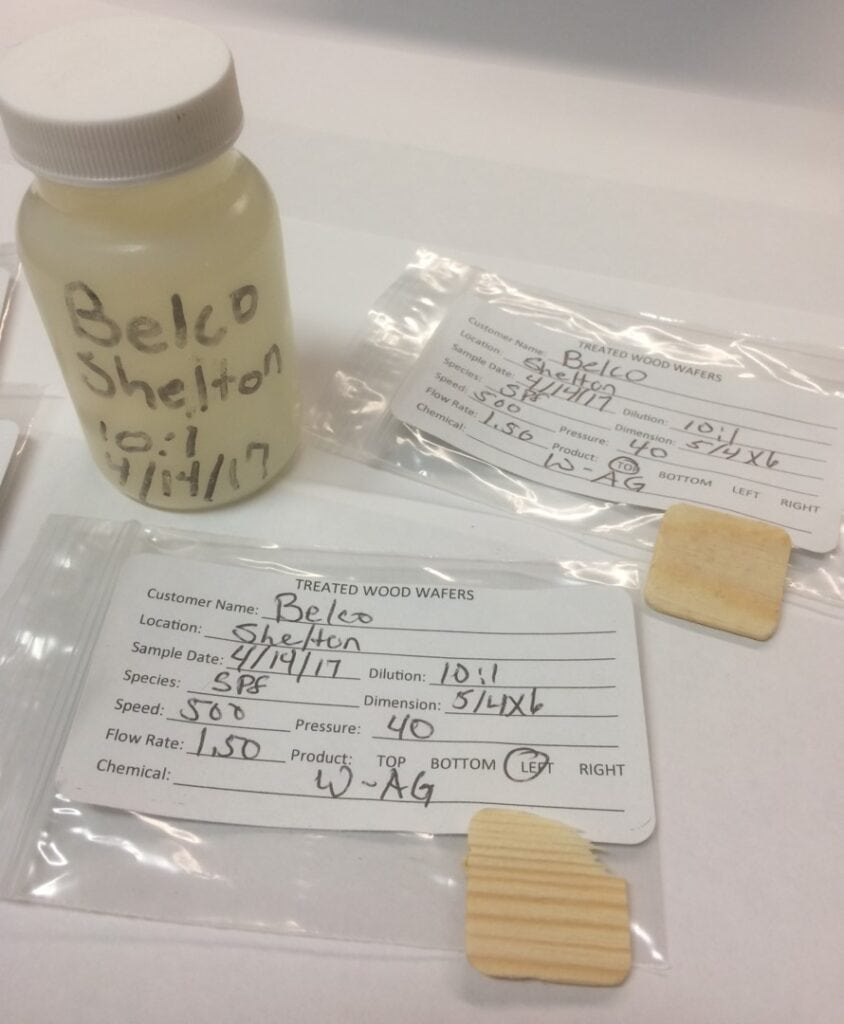

Modern wood treatments are evolving to be both highly effective and environmentally conscious. One standout innovation is Wolman® AG, a non-metallic, EPA-approved treatment designed to repel fungi, termites, and decay without relying on heavy metals like copper. Companies such as Lonza (maker of Wolman) and Arch Treatment Technologies (now a part of Lonza) have driven the adoption of safer solutions across residential and commercial markets. These treatments are now used in trim, fascia, and siding products that prioritize both performance and sustainability.

2. Thermally Modified Wood

The origin story for thermally modified wood dates back over a century. In 1915, Harry Tiemann of the U.S. Forest Products Laboratory first documented the benefits of heat-treating wood to reduce moisture absorption and improve durability. The modern commercial breakthrough, however, began in Finland during the 1990s, where the ThermoWood® process was standardized and brought to market. This technique involves heating wood in a low-oxygen environment to improve its dimensional stability and resistance to decay without using chemicals at all. It is most often used today for siding, decking, and exterior applications where the natural wood aesthetic and long-term durability are concentric design requirements. The process does seem to change the bond strength of wood, however. For this reason, thermally modified wood is not typically used for structural framing or other load-bearing applications. It is increasingly favored in high-end residential and commercial projects for its beauty and long-term performance.

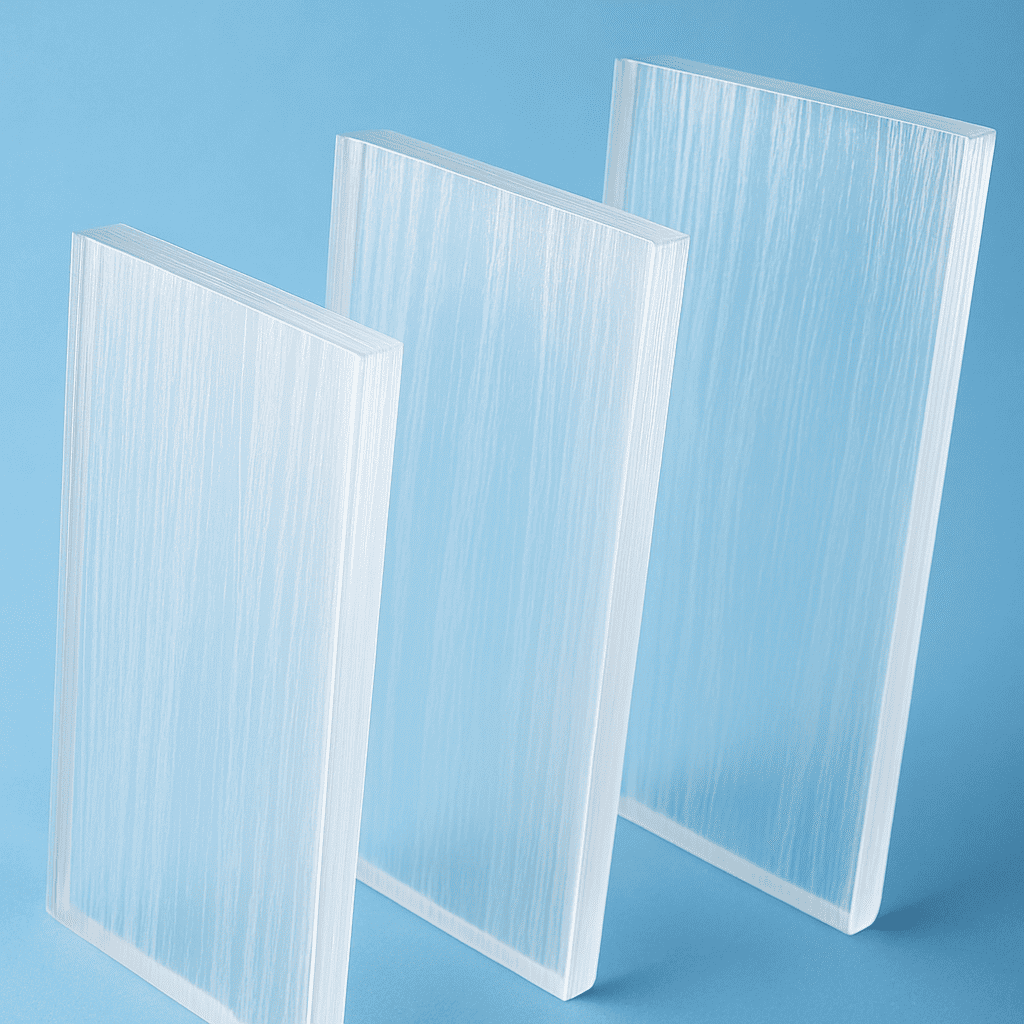

3. Transparent Wood

One fascinating development is the upcoming information on transparent wood. It is potentially becoming a viable alternative to glass. Developed by researchers at Sweden’s KTH Royal Institute of Technology and refined in labs at the University of Maryland, transparent wood is created by removing lignin from rubber wood and infusing it with a transparent polymer. The material offers five times the thermal insulation of glass and better impact resistance, making it a promising material for energy-efficient buildings and solar panel substrates. While not commercially available at scale yet, this innovation is being watched closely by sustainable design pioneers and innovators in our industry.

4. Cross-Laminated Timber (CLT)

CLT has emerged as a true game-changer in mass timber construction. Created by layering wood panels crosswise and bonding them together, CLT provides exceptional strength, seismic resilience, and fire resistance. It’s widely used in mid-rise and even high-rise construction as a sustainable alternative to concrete and steel. Notable adopters include Structurlam and SmartLam, whose products have been featured in large-scale projects across North America. CLT reduces carbon footprints significantly and helps sequester carbon over the entirety of a structure’s lifecycle.

5. Lignin-Based Carbon Fiber

The implications of this innovation could genuinely be the most far-reaching in terms of industries impacted. Carbon fiber made from wood? Yes, thanks to lignin, the natural binding element in wood. Several organizations are pioneering the transformation of lignin into lightweight, high-strength carbon fiber. This really could revolutionize the automotive, aerospace, and construction industries by offering a renewable, lower-cost alternative to petroleum-based carbon fiber. The potential to reduce dependence on fossil fuels and increase the value of forest by-products is, in and of itself, astounding.

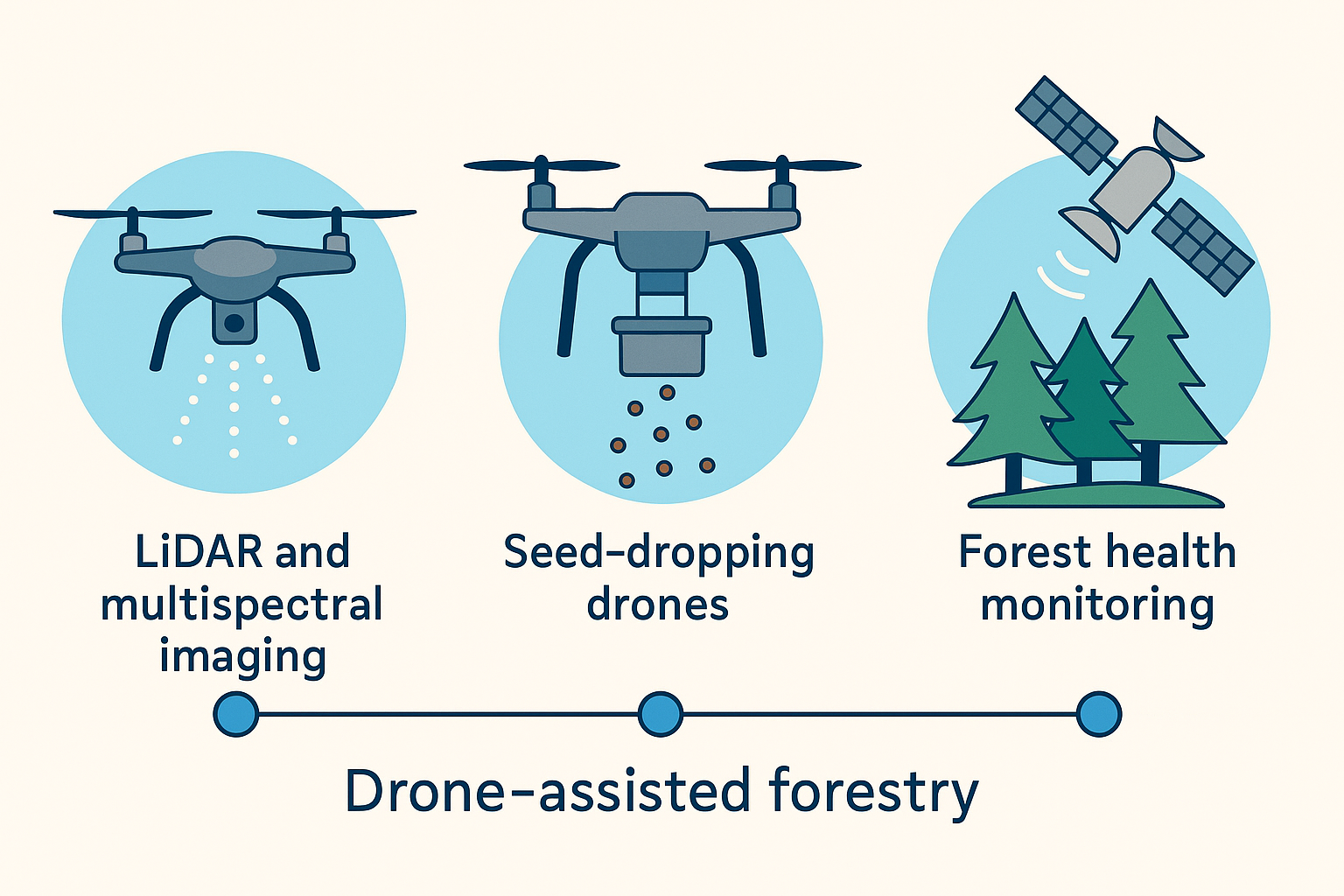

6. AI & Drone-Assisted Forestry

While the artificial intelligence boom swells and crests, it almost seems impossible to innovate fast enough. But many are harnessing data and adjusting processes already at lightning speed. For example, drones equipped with LiDAR and multispectral imaging are becoming indispensable tools for foresters. Companies like DroneSeed are replanting forests faster and more efficiently after wildfires using swarms of seed-dropping drones. Meanwhile, AI systems analyze satellite data to monitor forest health, predict pest outbreaks, and optimize harvest cycles. These technologies are accelerating reforestation efforts and ensuring more sustainable forest management on a grand scale.

7. Biochar Utilization

Biochar, a charcoal-like substance made from organic waste, is gaining momentum for its ability to lock atmospheric carbon into a chemically inactive form and improve soil health. It’s used in agriculture to retain nutrients and water in the soil, and in forestry to rehabilitate degraded land. Companies like Wakefield Biochar and Carbo Culture are scaling up biochar production as a contribution to broader carbon capture strategies. In forestry, converting tree waste into biochar turns logging by-products into climate-positive materials.

Spotlight on Industry Leadership: Belco’s Unique Two-Step Process

Belco Forest Products has been innovating the forest products space since 1978, but the company made its most disruptive pivot in the early 2000s when it began offering preservative-treated exterior trim as a standard, not a costly upsell. This bold move redefined expectations in the exterior trim industry, making high-performance, decay-resistant wood more accessible to builders nationwide.

Belco is vetted and trusted by builders everywhere for their true two-step preservative and prime treatment process. The first step deeply infuses wood with Wolman® AG, an eco-friendly, non-metallic preservative (noted above as a game-changing innovation on its own). The second step is application of a factory-applied primer, enhancing moisture resistance and ensuring immediate job-site readiness. Explore what makes Belco XT® Fascia and exterior trim products the choice for discerning builders and architects.

The Future of Wood Treatment and Sustainable Forestry

As National Forest Week reminds us, our commitment to creative and sustainable practices in wood treatment is far-reaching. Looking forward, ongoing innovation points to increasing sustainable and more efficient treatments. Emerging areas to watch are biological preservatives, advanced polymer-infused wood solutions, blockchain technology for supply-chain transparency, and AI-driven quality control systems. Each advancement could further support sustainability and responsible resource management in the industry.