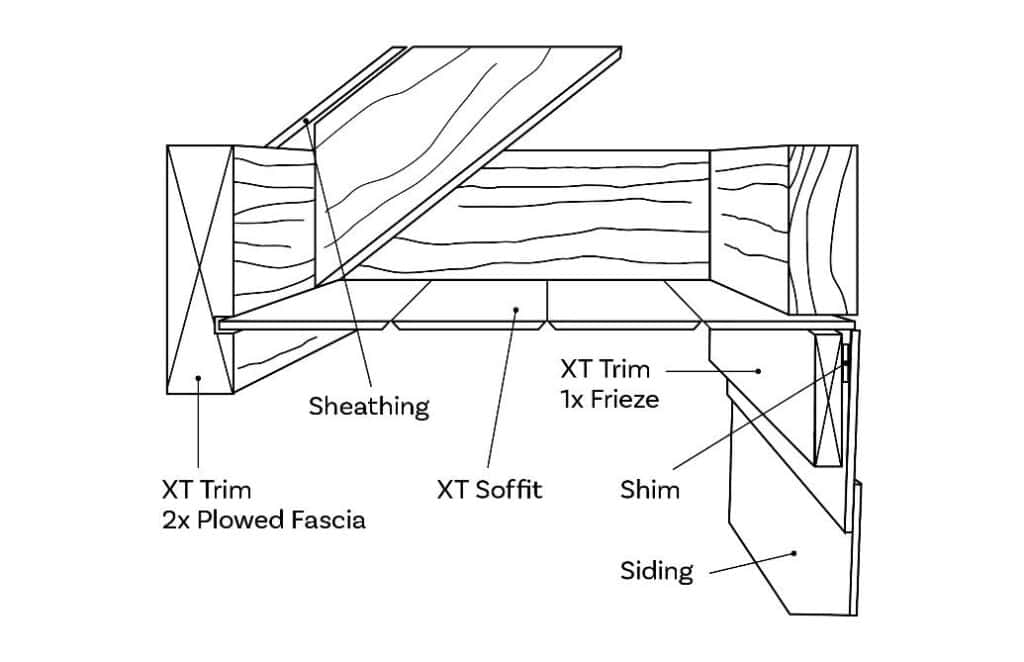

Fascia is the workhorse of a roof system. It ties the rafters together and keeps the gutter system intact during rain events. It is common to install a utility grade sub fascia prior to installing the finished fascia board. However some builders skip the sub fascia altogether and install an appearance grade, structural fascia board such as a 2×6. To some degree, regional variations depend on whether the design incorporates a closed soffit or exposed overhang, as well as local climate based considerations.

Rain Country

In the Pacific Northwest for example, exposed overhangs are standard practice. Rafters are plumb cut at the tail end and run 12-24 inches beyond the top plate of the wall. Many builders choose a 5/4” fascia product either 6 or 8 inches deep which is fastened directly to the rafter tails to complete the look. Most builders also install a 1×2 drip edge and flash the edge. Many builders use a 5/4” or 2” fascia board as both products are structurally adequate.

Additionally, since fascia in the PNW is largely hidden behind the gutter the choice often depends on aesthetic design preference. However, for barge-board (the raked piece of fascia on a gable end that ties into the fascia at the gutter line) a 2” product is recommended due to a lack of available nailing surface. In terms of stability, 2” bargeboards perform better than 5/4” in areas where there is less nailing surface. This ties into a 5/4” or 2” fascia just as easily.

Hurricane Alley

Florida has seen widespread soffit failures from recent hurricanes. Nearly all of them are the result of poor detailing or improperly specified products. To improve soffit installation, the 7th Edition (2020) FBCR contains a section specifically addressing design wind loads and installation details for soffits. Prescriptive codes have been added for various soffit materials including vinyl, fiber-cement, hardboard, and wood structural panel soffit. Changes include limiting the span of vinyl soffits to 12” and they must be fastened at the wall and fascia board.

There are various fascia systems used in this region. From Miami to Daytona beach, a primed and combed 2×6 or 2×8 is used for fascia. Since it is appearance grade, it makes for a great one and done option. Install it, paint it and enjoy it! However, builders on the Florida west coast use a multitude of different fascia systems ranging from the one and done solution to framing lumber wrapped with aluminum or vinyl. Typically the style of house dictates the fascia board style. For example, homes with vinyl soffit often match style with vinyl wrapped fascia, and homes with aluminum soffit use aluminum wrapped fascia. Belxo XT® fascia board is a standout choice as it is the quickest to install, best looking, and most affordable option in the market. Furthermore, the previous mentioned soffit systems tie into the back side of Belco fascia seamlessly.

Texas Two-Step

Texas has two different approaches to fascia board installation. In central Texas, the majority of new construction features 2×6 or 2×8 plowed, primed and combed fascia. However in Houston and DFW, the use of sub fascia is more widespread. To complete these assemblies, a thin 5/16×6” fiber cement or 9/16×6” OSB product is attached to the face of the band.

Rocky Mountains

In dry Colorado, about one-third of the builders rely on the sub fascia method. It is often capped with a thin profile OSB or cementitious product. The remaining 70% use a structural 2×6, combed and primed finish.

Colorado’s present fascia board practices are also predominantly a two-step system. A structural utility grade sub fascia is installed to the truss tails or outlookers by the framer. In a separate step, a thin textured fascia of engineered wood material is installed as the appearance cap. This two step process innately comes with a potential risk of moisture infiltration between the two pieces. This often remains unnoticed until years later. In contrast to alternatives like Belco XT®, engineered wood products typically lack primer on their backside as well.

Utah builders often use the same two-step process, however aluminum or vinyl fascia and soffit systems are more common on tract homes. These metal and vinyl systems are susceptible to expansion in warm weather, and contraction in cold weather.

Desert High Heat

Phoenix, Arizona is a city that thrives in extremes. In some months, temperatures can reach 125 degrees. Two feet of snow can fall in Flagstaff while Phoenix residents are wearing shorts and sandals.

For fascia applications the Phoenix market leans heavily toward primed wood fascia board. The fastest growing primed wood product in Phoenix over that past five years is Belco XT® primed SPF fascia with a real preservative treatment under the primer as standard. Belco’s XT® 2×6 and 2×8 trim is a structural fascia that can be applied directly to the plated-truss tails and the outlookers. The quality and stability of Belco XT® Trim, along with a six-mil primer and the preservative treatment, has stood up to the extreme weather of the Arizona desert.

Which fascia method is better?

Both options possess distinct advantages and drawbacks, warranting a comprehensive examination of their key features:

- Material costs- The typical fascia board for both OSB and fiber cement are less than 1” thick. They appear to have a much lower price point than structural 2×6. However, comparing the price per foot for each product reveals a different story. Board footage takes into account the three-dimensional volume of each product for a true apple-to-apple comparison. On average fiber cement is 20% higher per board foot while osb typically runs 50% higher per board foot than 2×6 SPF.

- Waste factors- Fiber cement is straight, and every plank looks identical. But it’s very brittle, especially at 5/16” thick. It’s common to see 20-30% breakage. Long 16-foot pieces can break if mishandled. Edge swell may occur if the product is left out in the rain. Solid wood can be prone to imperfections such as knots, wane, and warping. Nevertheless, specialty wood manufacturers recognize this and have innovated manufacturing methods to rival artificial counterparts. Consequently, modern primed wood fascia boasts a remarkably low waste factor.

- Labor- Primed wood fascia board is a single step installation. OSB and fiber cement require a sub fascia making it a two-stage build. Solid wood also outperforms its man-made counterparts in workability. You can’t hang Christmas lights from a piece of cement and puncturing into OSB could prove detrimental over time since the wood strands inside have a tendency to “mushroom” with moisture intrusion.

- Aesthetics- Both fiber cement and OSB are designed to emulate a wood-like appearance as solid wood is the aesthetic standard. Nothing can replace the warmth and beauty of real, natural wood fascia board.

Conclusion

Fascia boards serve as integral components within roofing systems, facilitating structural cohesion and drainage management. Regional practices vary significantly, reflecting factors such as climate, architectural design, and material availability. While diverse approaches exist, the choice between engineered and traditional wood fascia board requires considerations of cost, durability, labor requirements, and aesthetic appeal. Each method presents distinct advantages and drawbacks, necessitating careful evaluation based on project-specific needs and environmental factors. All things considered, Belxo XT® Trim exterior 2×6 and 2×8 fascia boards eliminate the need for sub fascia and offer an affordable, reliable, and beautiful trim option.