If time and tide wait for no man, then factory and fabrication wait for no builder. The pandemic has taught us all to rethink our way of life and work. For the construction industry, that means exploring options old and new. This article digs into the benefits and pitfalls of factory-built homes and modular construction. Is your firm ready to test the pre-fab waters?

Define Modular Construction

Modular building is the system of delivering factory-built “modules” to a prepared building site. An experienced crew then typically sets them by crane. Modules often include insulation, drywall, windows, doors, siding, roofing, cabinetry, plumbing and electrical. Additionally, they conform to local and national building codes. They also meet zoning requirements for site-built homes. Styles vary from log cabin, to gabled timber frame. Rafters, trusses and dormers are additional options as well.

Furthermore, panelized building is the system of delivering factory-built wall, floor or roof “panels” to the prepared building site. Here, general framing crews set them. These walls may also include various material add-ons. They might also conform to local and national building codes.

Additionally, a manufactured home is a complete, factory-built home. It is attached to a metal frame and is delivered to the homesite, usually in two sections. Often referred to as HUD homes, these homes meet the HUD building codes and follow specific local zoning ordinances.

Benefits to Modular and Panelized Construction

Ken Semler is a vice president of the Modular Home Building Association and longtime evangelist. He believes that virtually any design of any size can be translated into a modular construction project. Over the years, Ken has built 10,000 s.f. mansions, to 2-box ranch-style homes, and everything in between.

“There is no such thing as a modular home,” says Ken. “Modular is a type of construction, where we take the floor plan and break it into modules and construct the modules in a controlled factory setting. I tell all my customers it’s always summertime in the factory and it never rains.” Ken’s firm supports a group of more than 30 modular factories throughout the US. This short video is a great introduction for anyone considering modular construction.

Benefits of Modular

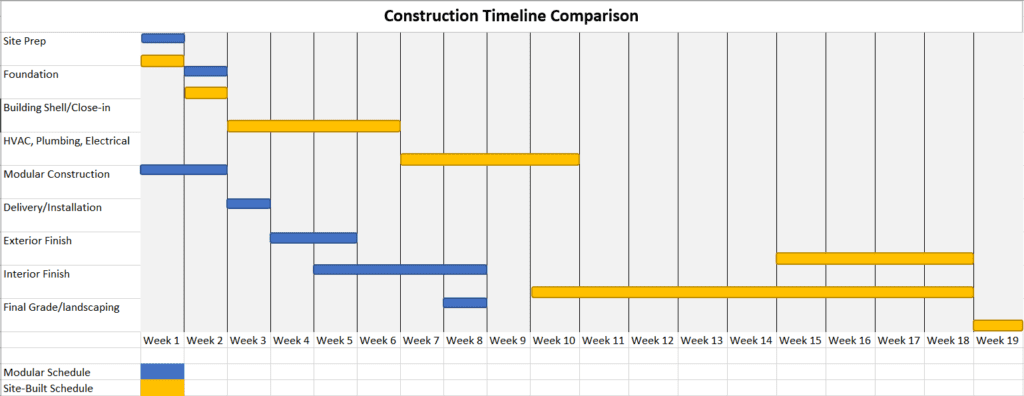

- A skilled and consistent labor force gets very good at what they do. Modular construction is 30 to 50% faster than site-built.

- Over 50% of the hard costs are at the factory which reduces change orders and waste.

- Modules of 16’ x 64’ dimension are common at most factories.

- Reduced exposure to acts of God, price swings and loan expirations

- Tight – tolerances, project management and control of schedules

Obstacles to Consider

New way of thinking about your designs – inches matter:

- Materials, colors and other options must be early and decisive – change orders get expensive

- Can the project be delivered and set?

- What physical obstructions on route and at site?

- Crane and pad location

- Carrier location and removal

- Module staging area

- On-site by others vs. factory installed

- Dry-in weather set vs rough set

- Scheduling is more critical than site-built

When dipping a toe in modular waters, most experts recommend a hybrid approach. Plus, production builders are well-suited to start with factory-built floor and wall panels. As the team’s comfort level increases, more complexity may be added. With skilled field labor growing scarcer every year, the growth in modular is forecast to reach $20B by 2024 with 5-7% CAGR.

Modular Construction Advantages

While the site prep and foundation work are under way, so are the modules. The result is a compressed building cycle, which saves an average of 10 weeks to completion.